Description

Quick jet nozzle can be made through mould pressing glass fiber reinforced polypropylene (containing 25% of fiber), carbon fiber reinforced polypropylene (containing 40% of fiber), or PVDF, with the advantages of high intensity, wear-resistance and chemical corrosion resistant, avoiding washing liquid clotting or accumulation. It is quite applicable to dry-cleaning, rinsing and cleansing using phosphate, acids, solvents and other corrosive liquids. The highest temperature of the glass fiber reinforced polypropylene is 82°, that of the carbon fiber reinforced polypropylene is 120°, and the PVDF is a kind of high purity material without being added any dyestuff.

Wide flow choices

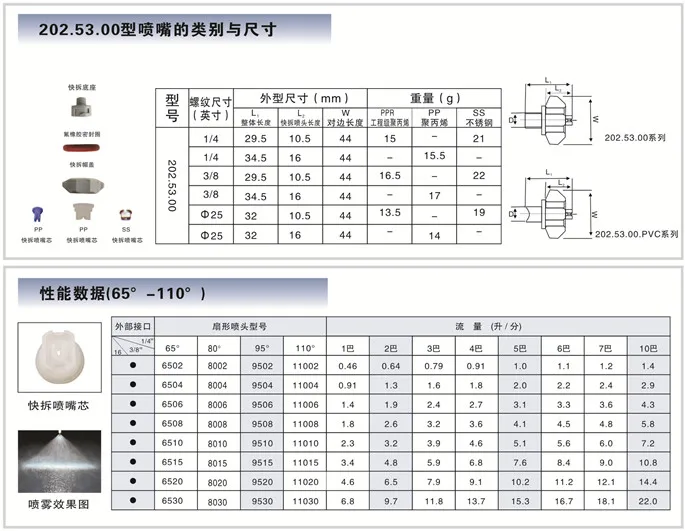

There are three standards for the shower nozzle: 1/8″, 1/4″ and 3/8″. The inbuilt O-shaped NBR seal ring ensures absolute closure of between the nozzle body and the shower nozzle. The quick jet shower nozzle adopts an easy-to-grab design; the shower nozzle is in QC fan shape or QB solid cone-shape, providing two correspondent spraying modes with various choices of flow and angles.

2.Cooling

3.Humidifying

4.Chemical industry

5.Dust control

6.Cleaning