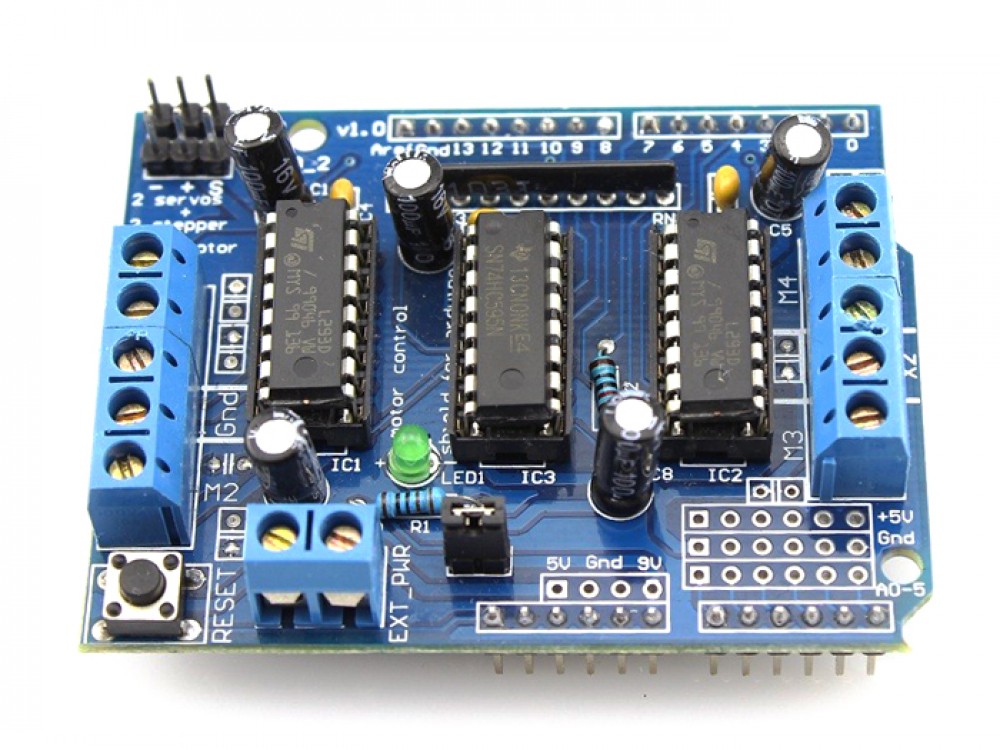

To increase the maximum current, the L293D allows extra chips with “piggyback”. Piggyback is soldering one or two or three extra L293D drivers on top of the L293D drivers on the board to increase the maximum current. The L293D allows parallel operation.

The Motor Shield is able to drive 2 servo motors, and has 8 half-bridge outputs for 2 stepper motors or 4 full H-bridge motor outputs or 8 half-bridge drivers, or a combination.

Quick start

Supply the power either through the Arduino Board or the power header of the Motor Shield. Only if the Arduino Board and the Shield use a separate power supply, the jumper must be removed.

Load the sketch below in Arduino (the sketch is not for stepper motors) and follow the example in the sketch to drive your DC-motors or solenoids or lights.

Code

The sketch below is a simple sketch to use the Motor Shield without the Adafruit library. This code does not support stepper motors, but every output can also be used to drive solenoids or relays.

The code uses Arduino code as much as possible.

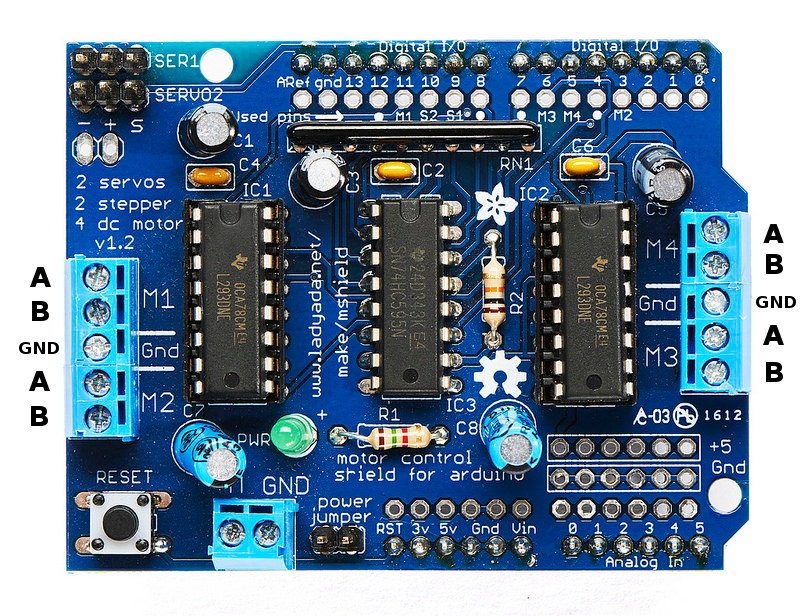

// Simple Motor Shield sketch // ----------------------------------- // // By arduino.cc user "Krodal". // June 2012 // Open Source / Public Domain // // Using Arduino 1.0.1 // // A simple sketch for the motor shield, // without using the Adafruit library. // // The outputs can be used for DC-motors // (either full H-bridge or just On and Off), lights, // relays, solenoids, etc. // But stepper motors can not be used ! // Servo motors can be used with the default Servo library. // // A maximum of 4 DC motors can be used with full-bridge, // or a maximum of 8 normal outputs, or a combination. // Two servo motors can always be used, they use the +5V // of the Arduino board, so the voltage regulator could // get hot. // // Tested with an Ebay clone with the Arduino Uno. // // Parts of the code are from an old Adafruit Motor Shield // library, which was public domain at that time. // This code is also public domain // // This simplified program is using the normal // Arduino library functions as much as possible. // // The motors will make a whistling sound, // due to the analogWrite() PWM frequency. // The Adafruit library is specifically designed to avoid // this, so use the Adafruit library for a better result. // // // // Connector usage // --------------- // The order is different than what you would expect. // If the Arduino (Uno) board is held with the USB // connector to the left, the positive (A) side is // at the top (north), and the negative (B) side is // the bottom (south) for both headers. // // Connector X1: // M1 on outside = MOTOR1_A (+) north // M1 on inside = MOTOR1_B (-) // middle = GND // M2 on inside = MOTOR2_A (+) // M2 on outside = MOTOR2_B (-) south // // Connector X2: // M3 on outside = MOTOR3_B (-) south // M3 on inside = MOTOR3_A (+) // middle = GND // M4 on inside = MOTOR4_B (-) // M4 on outside = MOTOR4_A (+) north // // // ------------------------------- // | -+s | // | -+s | // M1 A | | M4 A // M1 B | | M4 B // GND | | GND // M2 A | | M3 A // M2 B | | M3 B // | ..... | // ------------------------------- // + - // // // // Pin usage with the Motorshield // --------------------------------------- // Analog pins: not used at all // A0 ... A5 are still available // They all can also be used as digital pins. // Also I2C (A4=SDA and A5=SCL) can be used. // These pins have a breadboard area on the shield. // Digital pins: used: 3,4,5,6,7,8,9,10,11,12 // Pin 9 and 10 are only used for the servo motors. // Already in use: 0 (RX) and 1 (TX). // Unused: 2,13 // Pin 2 has an soldering hole on the board, // easy to connect a wire. // Pin 13 is also connected to the system led. // I2C is possible, but SPI is not possible since // those pins are used. // #include <Servo.h> // Arduino pins for the shift register #define MOTORLATCH 12 #define MOTORCLK 4 #define MOTORENABLE 7 #define MOTORDATA 8 // 8-bit bus after the 74HC595 shift register // (not Arduino pins) // These are used to set the direction of the bridge driver. #define MOTOR1_A 2 #define MOTOR1_B 3 #define MOTOR2_A 1 #define MOTOR2_B 4 #define MOTOR3_A 5 #define MOTOR3_B 7 #define MOTOR4_A 0 #define MOTOR4_B 6 // Arduino pins for the PWM signals. #define MOTOR1_PWM 11 #define MOTOR2_PWM 3 #define MOTOR3_PWM 6 #define MOTOR4_PWM 5 #define SERVO1_PWM 10 #define SERVO2_PWM 9 // Codes for the motor function. #define FORWARD 1 #define BACKWARD 2 #define BRAKE 3 #define RELEASE 4 // Declare classes for Servo connectors of the MotorShield. Servo servo_1; Servo servo_2; void setup() { Serial.begin(9600); Serial.println("Simple Motor Shield sketch"); // Use the default "Servo" library of Arduino. // Attach the pin number to the servo library. // This might also set the servo in the middle position. servo_1.attach(SERVO1_PWM); servo_2.attach(SERVO2_PWM); } void loop() { // Suppose there are two servo motors connected. // Let them move 180 degrees. servo_1.write(0); delay(1000); servo_1.write(180); delay(2000); servo_2.write(0); delay(1000); servo_2.write(180); delay(2000); // Suppose there is a relay, or light or solenoid // connected to M3_A and GND. // Note that the 'speed' (the PWM, the intensity) // is for both M3_A and M3_B. // The output is a push-pull output (half bridge), // so it can also be used to drive something low. // The 'speed' (the PWM, the intensity) can be set // to zero, that would make the output disabled // and floating. motor_output(MOTOR3_A, HIGH, 255); delay(2000); motor_output(MOTOR3_A, LOW, 255); // Suppose a DC motor is connected to M1_A(+) and M1_B(-) // Let it run full speed forward and half speed backward. // If 'BRAKE' or 'RELEASE' is used, the 'speed' parameter // is ignored. motor(1, FORWARD, 255); delay(2000); // Be friendly to the motor: stop it before reverse. motor(1, RELEASE, 0); delay(500); motor(1, BACKWARD, 128); delay(2000); motor(1, RELEASE, 0); } // Initializing // ------------ // There is no initialization function. // // The shiftWrite() has an automatic initializing. // The PWM outputs are floating during startup, // that's okay for the Motor Shield, it stays off. // Using analogWrite() without pinMode() is valid. // // --------------------------------- // motor // // Select the motor (1-4), the command, // and the speed (0-255). // The commands are: FORWARD, BACKWARD, BRAKE, RELEASE. // void motor(int nMotor, int command, int speed) { int motorA, motorB; if (nMotor >= 1 && nMotor <= 4) { switch (nMotor) { case 1: motorA = MOTOR1_A; motorB = MOTOR1_B; break; case 2: motorA = MOTOR2_A; motorB = MOTOR2_B; break; case 3: motorA = MOTOR3_A; motorB = MOTOR3_B; break; case 4: motorA = MOTOR4_A; motorB = MOTOR4_B; break; default: break; } switch (command) { case FORWARD: motor_output (motorA, HIGH, speed); motor_output (motorB, LOW, -1); // -1: no PWM set break; case BACKWARD: motor_output (motorA, LOW, speed); motor_output (motorB, HIGH, -1); // -1: no PWM set break; case BRAKE: // The AdaFruit library didn't implement a brake. // The L293D motor driver ic doesn't have a good // brake anyway. // It uses transistors inside, and not mosfets. // Some use a software break, by using a short // reverse voltage. // This brake will try to brake, by enabling // the output and by pulling both outputs to ground. // But it isn't a good break. motor_output (motorA, LOW, 255); // 255: fully on. motor_output (motorB, LOW, -1); // -1: no PWM set break; case RELEASE: motor_output (motorA, LOW, 0); // 0: output floating. motor_output (motorB, LOW, -1); // -1: no PWM set break; default: break; } } } // --------------------------------- // motor_output // // The function motor_ouput uses the motor driver to // drive normal outputs like lights, relays, solenoids, // DC motors (but not in reverse). // // It is also used as an internal helper function // for the motor() function. // // The high_low variable should be set 'HIGH' // to drive lights, etc. // It can be set 'LOW', to switch it off, // but also a 'speed' of 0 will switch it off. // // The 'speed' sets the PWM for 0...255, and is for // both pins of the motor output. // For example, if motor 3 side 'A' is used to for a // dimmed light at 50% (speed is 128), also the // motor 3 side 'B' output will be dimmed for 50%. // Set to 0 for completelty off (high impedance). // Set to 255 for fully on. // Special settings for the PWM speed: // Set to -1 for not setting the PWM at all. // void motor_output (int output, int high_low, int speed) { int motorPWM; switch (output) { case MOTOR1_A: case MOTOR1_B: motorPWM = MOTOR1_PWM; break; case MOTOR2_A: case MOTOR2_B: motorPWM = MOTOR2_PWM; break; case MOTOR3_A: case MOTOR3_B: motorPWM = MOTOR3_PWM; break; case MOTOR4_A: case MOTOR4_B: motorPWM = MOTOR4_PWM; break; default: // Use speed as error flag, -3333 = invalid output. speed = -3333; break; } if (speed != -3333) { // Set the direction with the shift register // on the MotorShield, even if the speed = -1. // In that case the direction will be set, but // not the PWM. shiftWrite(output, high_low); // set PWM only if it is valid if (speed >= 0 && speed <= 255) { analogWrite(motorPWM, speed); } } } // --------------------------------- // shiftWrite // // The parameters are just like digitalWrite(). // // The output is the pin 0...7 (the pin behind // the shift register). // The second parameter is HIGH or LOW. // // There is no initialization function. // Initialization is automatically done at the first // time it is used. // void shiftWrite(int output, int high_low) { static int latch_copy; static int shift_register_initialized = false; // Do the initialization on the fly, // at the first time it is used. if (!shift_register_initialized) { // Set pins for shift register to output pinMode(MOTORLATCH, OUTPUT); pinMode(MOTORENABLE, OUTPUT); pinMode(MOTORDATA, OUTPUT); pinMode(MOTORCLK, OUTPUT); // Set pins for shift register to default value (low); digitalWrite(MOTORDATA, LOW); digitalWrite(MOTORLATCH, LOW); digitalWrite(MOTORCLK, LOW); // Enable the shift register, set Enable pin Low. digitalWrite(MOTORENABLE, LOW); // start with all outputs (of the shift register) low latch_copy = 0; shift_register_initialized = true; } // The defines HIGH and LOW are 1 and 0. // So this is valid. bitWrite(latch_copy, output, high_low); // Use the default Arduino 'shiftOut()' function to // shift the bits with the MOTORCLK as clock pulse. // The 74HC595 shiftregister wants the MSB first. // After that, generate a latch pulse with MOTORLATCH. shiftOut(MOTORDATA, MOTORCLK, MSBFIRST, latch_copy); delayMicroseconds(5); // For safety, not really needed. digitalWrite(MOTORLATCH, HIGH); delayMicroseconds(5); // For safety, not really needed. digitalWrite(MOTORLATCH, LOW); }